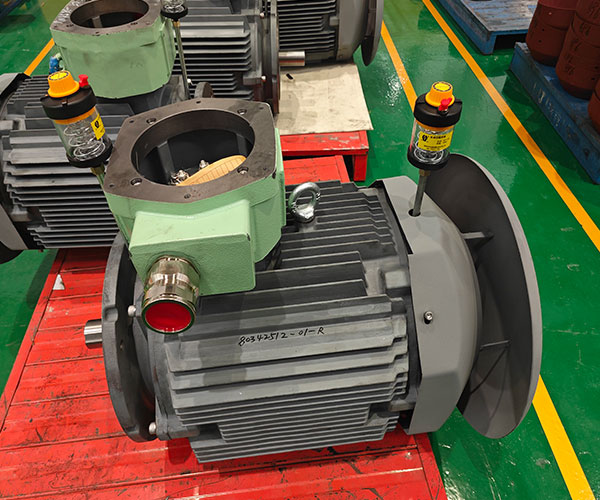

A large textile factory in Southeast Asia was struggling with rising electricity bills and frequent motor breakdowns due to outdated machinery. Their production relied heavily on continuous operation of motors driving looms and compressors, but energy waste and maintenance downtime were cutting into profits. To overcome these challenges, the company chose to upgrade its systems with Wolong Nanyang Motor high efficiency induction motors.

These motors were engineered to deliver maximum energy savings through optimized rotor design, advanced copper winding technology, and reduced thermal losses. After installation, the textile plant reported over 18% savings in annual energy consumption, while unplanned downtime dropped by nearly 30% thanks to the improved durability and reliability of the motors.

In addition, the motors met international energy efficiency standards, which helped the facility align with local government incentives for sustainable industrial practices. The combination of lower energy costs, longer maintenance cycles, and compliance with efficiency regulations made the investment highly rewarding.

This case demonstrates how Wolong Nanyang Motor high efficiency induction motors not only support environmental goals but also deliver significant financial and operational benefits for energy-intensive industries worldwide.

Also See

high efficiency induction motor

Post time: Sep-03-2025